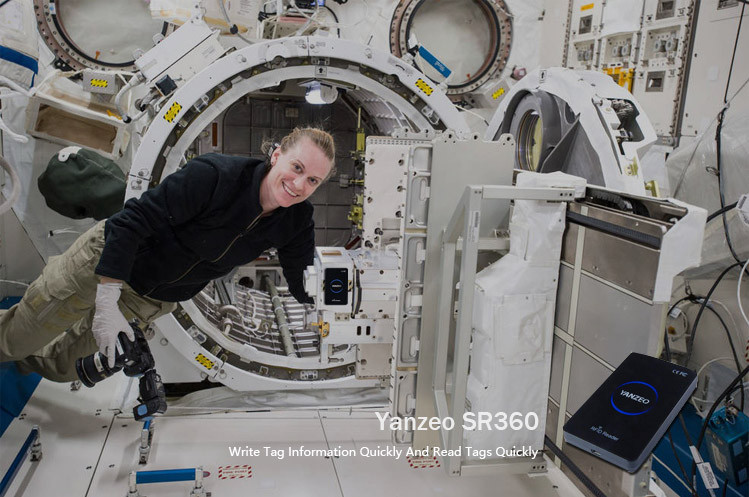

RFID went to heaven successfully! Material management in space is still very effective

01. Independently build the "Tiangong" space station. The innovative application of RFID goes into space

In the entire history of human manned spaceflight, there have been four series, a total of 12 space stations. In 1971, the first space station "Salute 1" weighing 18 tons was successfully launched. However, today, half a century later, there is only one International Space Station still in orbit, with a total weight of 420 tons.

The International Space Station is an international cooperative project, and its members include the United States, Russia, the European Union, Japan and Canada. Although China has repeatedly applied to join the construction of the International Space Station, it has repeatedly been led by the United States to oppose it. This shows that China's independent construction of its own space station is really helpless.

my country's space station was formally approved in 1992, and it has been developed for 30 years. According to the national plan, the "Tiangong" space station is expected to be completed in 2022. By 2024, the current International Space Station will be decommissioned, and by then, Tiangong-1 will become the only space station in orbit. In general, the success of Tiangong-1 will win a strong voice for my country in the field of space research and establish its own advantages in the field of human space exploration and research.

According to incomplete statistics, more than 1,000 new materials have emerged in the world in recent years, 80% of which have been developed under the aerospace technology. Among them, more than 2,000 aerospace technology achievements have been transplanted to the national economy.

The construction of the space station is a huge technology-intensive project with a wide range of implications. The daily operation of Tiangong-1 is also closely related to RFID technology.

It is understood that Sichuan Aerospace has deeply participated in the major construction of the "Tiangong" space station, responsible for the development of material management systems, handheld RFID readers and other areas and components that are closely related to the life of the astronauts. "Great flat floor" comfortable environment in space.

02.

RFID material management system greatly reduces the workload of astronauts

Although the new Tianhe core cabin has been transformed from the one-bedroom Tiangong laboratory into a large flat floor, its space is still very limited. Without a material management system for the space station, it is easy to cause chaos. Therefore, this time the space station uses a brand-new material information management system based on RFID technology.

Compared with the previous solution, the main improvement of the new system is the use of RFID radio frequency identification technology, that is, all materials are equipped with ultra-thin microchips and RFID embedded in plastic sheets, fiber paper and other materials. Label. After an item has a tag, it is equivalent to having a remark "identity ID", and the data can be transmitted through the RFID tag attached to the item to realize the purpose of automatically identifying and tracking the item.

Compared with the bar code system used by the International Space Station in the past, RFID radio frequency identification technology can realize batch, fast and accurate automatic identification, so that materials have a visualized information data flow. After astronauts scan materials through mobile phones, handheld RFID readers, tablets and other devices, they can realize the timely update of information such as material entry, retrieval, position movement, etc., so as to realize the digitization of material management and greatly reduce the cost of cleaning materials This is the fundamental reason why Chinese astronauts can clean up the core module in an orderly manner within 6 days.

The new RFID material management system is a part of my country's space station information system. Its purpose is to ensure the communication support of astronauts' life and work and the ability to perceive the status inside and outside the cabin through the unified construction of the space station information system, and to improve the management level of the space station. Reduce the non-essential workload of astronauts, so that they can free up energy to achieve more meaningful space results.

03. RFID material management "flowers" everywhere in all walks of life

In recent years, with the continuous popularization of digital management concepts, RFID technology has "flowered" in the field of material management, including books, electric power, manufacturing, transportation, medical care, banking, enterprises and other different industries.

In general, the RFID material management system adopts a management model of one item, one code, and each fixed asset will be bound with a unique ID, covering the entire life cycle of material purchase, procurement, warehousing to scrapping. Because RFID has a strong group reading ability, it can read hundreds of RFID tags in one second, which greatly improves the efficiency of material inventory.

According to the statistical data after actual application, after using the RFID material management system, the efficiency of enterprise material management inventory can be improved by more than 90%, the repurchase and loss rate of materials can be reduced by more than 40%, and the cost of material auditing can be reduced by more than 75%. The rate has increased by more than 30%.

In addition to the hardware system, the RFID material management system also needs to work hard on the software.

For example, the most common functions such as warehouse entry and exit management, asset inventory statistics, asset information query, and asset illegal entry and exit alarms are all implemented on the basis of software. With the help of a software platform, companies can understand asset conditions and trends in real time, and have clear data presentations on asset depletion, inventory management, and asset utilization.

With the continuous improvement of the informatization level of the entire society, the digital transformation of enterprises is an inevitable trend in the future. In this process, material management continues to develop in the direction of digitization, automation, and intelligence, and RFID technology will continue to exert greater advantages.