Application Of RFID Electronic Tag In Underground Pipeline

- RFID technology is introduced in daily management and maintenance to assist in the maintenance and repair of underground pipelines will more and more imporation. Urban underground pipelines are the blood vessels for the survival and development of the city, and the infrastructure to ensure the overall operation of the city. With the rapid development of society and economy, the underlying channels are also increasingly enriched and improved. However, because the underground pipelines are deeply buried in the ground, the maintenance work of the pipelines is more difficult, and the scope of the underground pipelines is large.

- Status Quo of Pipeline Maintenance Management

- Underground pipelines are generally laid below urban roads, and various pipelines are criss-crossed, forming an intricate underground pipeline network. Difficulty in identifying pipelines and traditional means of maintenance and management make underground pipeline management more and more difficult.

- Application of RFID Electronic Tag in Underground Pipeline

- 1. Pipeline identification

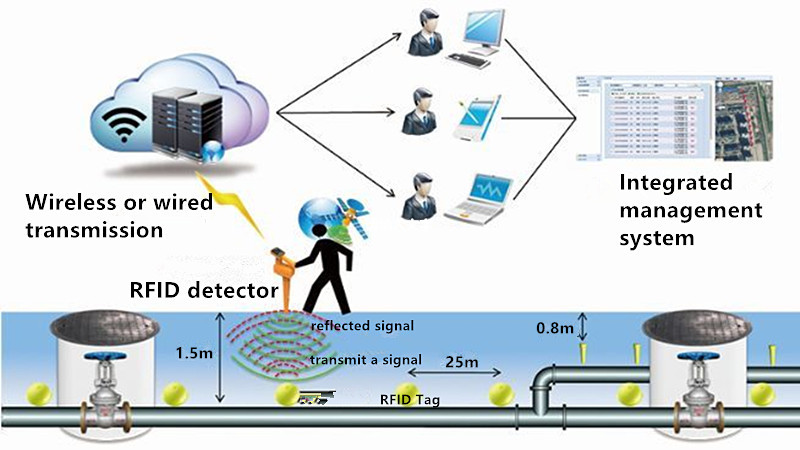

- Bury the RFID electronic tag that records the pipeline information next to the pipeline. In daily maintenance, using RFID sensor (PDA or RFID reading and writing device) to read the information of the tag, you can get the basic information such as the buried depth of the pipe, the size of the pipe diameter, and the type of the pipe. By identifying the unique code of the electronic label, the corresponding pipeline situation can be inquired at the background management service center to obtain the basic information of the pipeline.

- 2. Pipeline maintenance records

- After the pipeline maintenance work is completed, the maintenance information of the corresponding location is written in the background management service center, and the maintenance information of the pipeline can be directly obtained by reading the RFID electronic tag. At the same time, all pipeline maintenance information can be viewed in the background to avoid omissions, and the maintenance status and maintenance plan of the pipeline can be learned in detail.

- 3. Maintenance management personnel information registration

- Pipeline maintenance personnel have many inspection points, wide area, large mobility and poor supervision. After completing the corresponding work, the maintenance personnel write the corresponding task execution information through the handheld RFID reader, activate the electronic tag, and feed back the task information executed this time to the background management service center to implement each work task. Effectively regulate maintenance work.

- 4. Manage manhole covers

- The electronic tag is connected to the management center through the base station. Once the electronic tag leaves the reading range of the fixed reader, the base station can immediately transmit the information to the management center, so that the management center can obtain the information as soon as the manhole cover is abnormal. First, bury the electronic tag at the position of the manhole. After the acceptance center receives the report of the missing manhole cover, as long as the information of the electronic tag is read, the property rights unit can be immediately identified. It should be noted that the embedded point of the electronic label cannot be the manhole cover, otherwise the electronic label will be lost along with the manhole cover and cannot be read.