RFID System And WMS System Docking Advantages

- The RFID system and the warehouse system (WMS) are seamlessly connected, and the rapid response and security of data can be achieved through the real-time operation of RFID technology in the warehouse.

- Advantages Of RFID And WMS System Docking

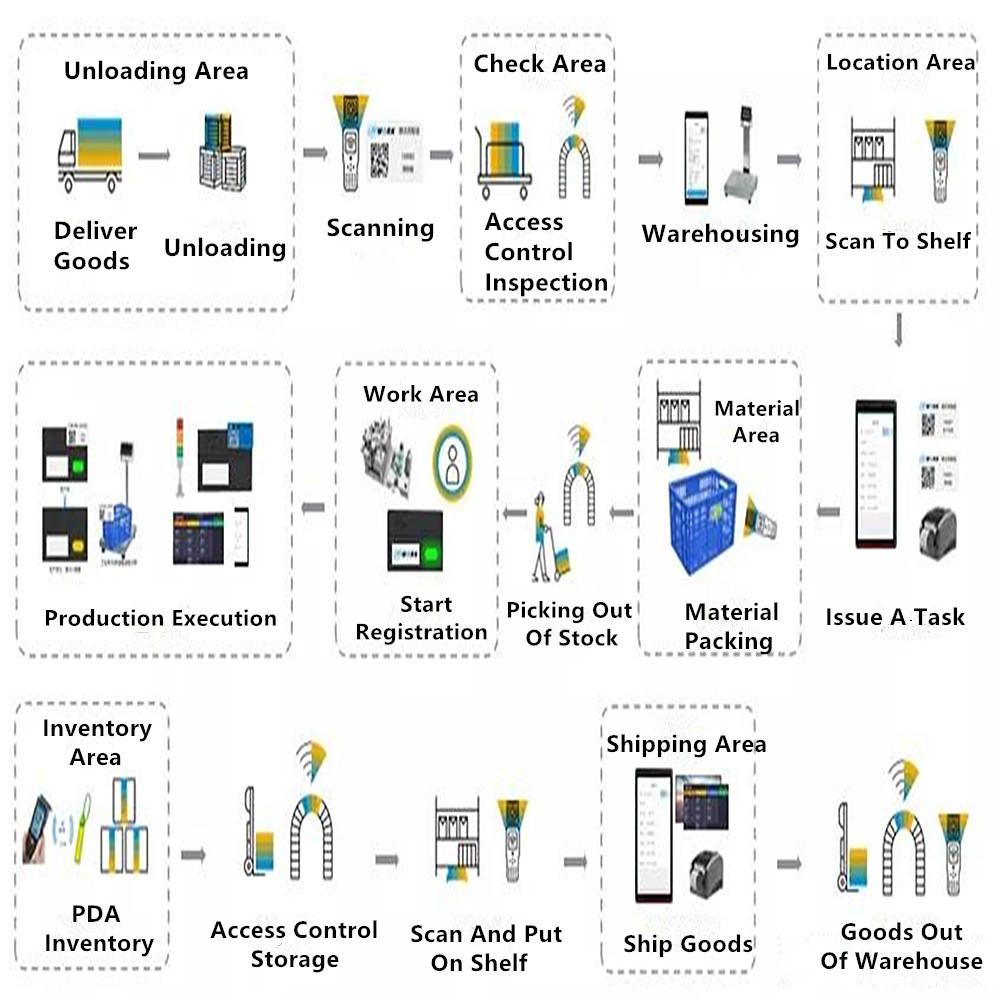

- When the goods enter the warehouse, install a fixed RFID reading device at the entrance of the warehouse or automatically identify the goods in the warehouse through a handheld device. Since each package is equipped with an electronic label, the single product can be identified. At the same time, due to the RFID Multi-readability, can identify many tags at one time, so as to realize fast storage.

- Personnel Management Can Be Divided Into Authority Personnel Management And VIP Personnel Management.

- 1 Authority personnel management

- * By distributing and wearing RFID cards to the personnel involved in warehouse management, the personnel and their authority are classified and managed;

- * Personnel information comparison function to judge personnel access rights;

- * Multi-level user authority, different personnel have different access authority and access authority;

- * The result output function, paired with the LCD display, the management results are easy to display;

- * The entry and exit time records passed by the system interact with the database, store data information, record in real time, and facilitate query;

- * The positioning of goods can be realized by deploying special RFID electronic tags on pallets, and at the same time, rapid inventory and in-out and out-of-stock operations can be realized.

- 2 VIP personnel management

- The leader wears an exclusive VIP staff tag. When the tag enters the antenna range, the LED display will display a preset welcome speech.

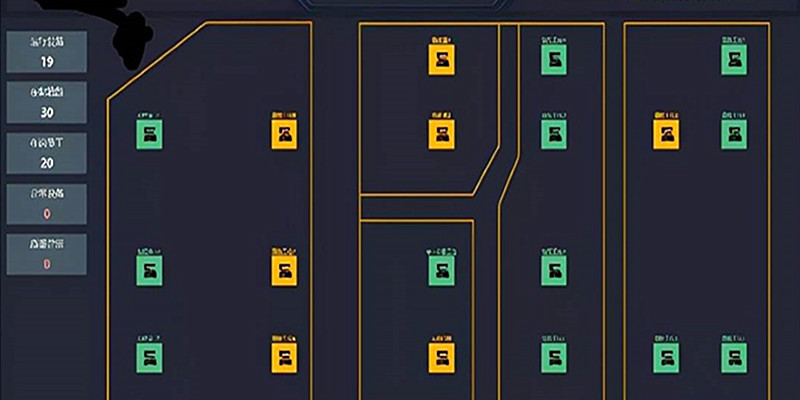

- 3 Visual warehouse management

- Click on each shelf to query the shelf inventory in real time. Each item has a label containing an electronic chip, which can display a quick inventory, keep abreast of inventory information, and facilitate control of reasonable inventory

- 4 Clear cargo space management

- Paste electronic labels on the shelves or exclusive cargo spaces to accurately locate the cargo positions. The significance of cargo location positioning is to quickly and accurately find the specific location of the goods; the corresponding cargo location label contains the specific cargo information on the cargo location, which is convenient for finding the goods; it is convenient for inventory, just scan the cargo location information during inventory. ; Facilitate automated operations.

- 5 Quick Inventory and Accurate Find Management

- Rapid inventory can be achieved through shelf labels and pallet labels, and target items can be quickly found due to the correspondence between shelf labels and items stored on the shelves

- 6 Turn ordinary forklifts into smart forklift management

- Install a special RFID reader and display on the forklift, send instructions to the driver through the system, and the forklift driver only needs to follow the commands provided by the system to operate.

- 7. Convert ordinary vehicles to intelligent transportation platforms

- Through the logistics transportation GPS monitoring service management system, we can manage and make good use of logistics transportation vehicles, keep abreast of the driving conditions of the vehicles, and ensure safety as much as possible.

- 8. Good scalability and forward-looking

- The system has good expansion ability, which can be seamlessly connected with the existing system of the enterprise, and has strong forward-looking ability, which can well realize future expansion.