What is RFID?

In daily shopping, I believe you must have experienced such "black technology".

When selecting products for checkout, there is no need to scan the barcodes of the products one by one.

Simply put all the products into the basket in the payment area, and the computer will immediately display the total amount of all the products you put in. The efficiency level allows us to complete the purchase without having to go through long queues.

The secret is hidden in these tags, which is the great RFID technology, but it is no longer considered a new technology. Wal Mart, the largest retailer in the United States, began to use it to check shelves as early as 2005; The work that used to require multiple people to spend several hours, now the system can complete it in only 30 minutes, significantly improving the efficiency of the supply chain. The system automatically generates electronic orders and updates the inventory of goods in real-time, saving warehouse space, improving capital flow rate, and effectively reducing labor costs in supply chain management, making information flow, logistics, and capital flow more compact and effective.

In industry, its application has greatly enabled more manufacturers to achieve the goal of reducing costs and increasing efficiency. In this issue, Xiaoming will teach everyone about RFID technology~

What is RFID?

Radio Frequency Identification (RFID) is an abbreviation for Radio Frequency Identification, which is a wireless communication technology that can identify specific targets and read and write related data through radio signals without establishing mechanical or optical contact between the recognition system and specific targets. It has the advantages of simultaneous recognition of multiple targets, long recognition distance, fast speed, large storage capacity, and strong anti-interference ability, and has unparalleled advantages in inventory efficiency.

Composition of RFID system

The RFID system is mainly composed of three parts: a reader, an electronic label, and a data management system.

RFID Tag

RFID electronic tags are composed of coupling components and chips, usually low voltage integrated circuits with coils, antennas, memory, and control systems. They can be divided into active, semi-active, and passive types, and are attached to objects to identify the target object, and have the function of storing information.

Each label has an Electronic Product Code (EPC), which is equivalent to an "ID card".

Reader

Reader, also known as signal receiver, is a device used to read label information and is the information control and processing center of the RFID system. Generally handheld or fixed.

data management system

Mainly processing the electronic tag data transmitted by the reader for parsing, while completing the functions required by the user.

The working principle of RFID technology

After the tag enters the reader, it receives the RF signal emitted by the reader, and uses the energy obtained from the induced current to send product information stored in the chip (Passive Tag, passive tag or passive tag), or the tag actively sends a signal of a certain frequency (Active Tag, active tag or active tag). The reader reads and decodes the information, and then sends it to the central information system for relevant data processing.

Thanks to the non-contact automatic identification technology of RFID, the target object is automatically identified and relevant data is obtained through radio frequency signals. The identification work does not require manual intervention, making it possible to work in various harsh environments, recognize high-speed moving objects, and simultaneously recognize multiple labels, making the operation fast and convenient.

The Application of RFID Technology

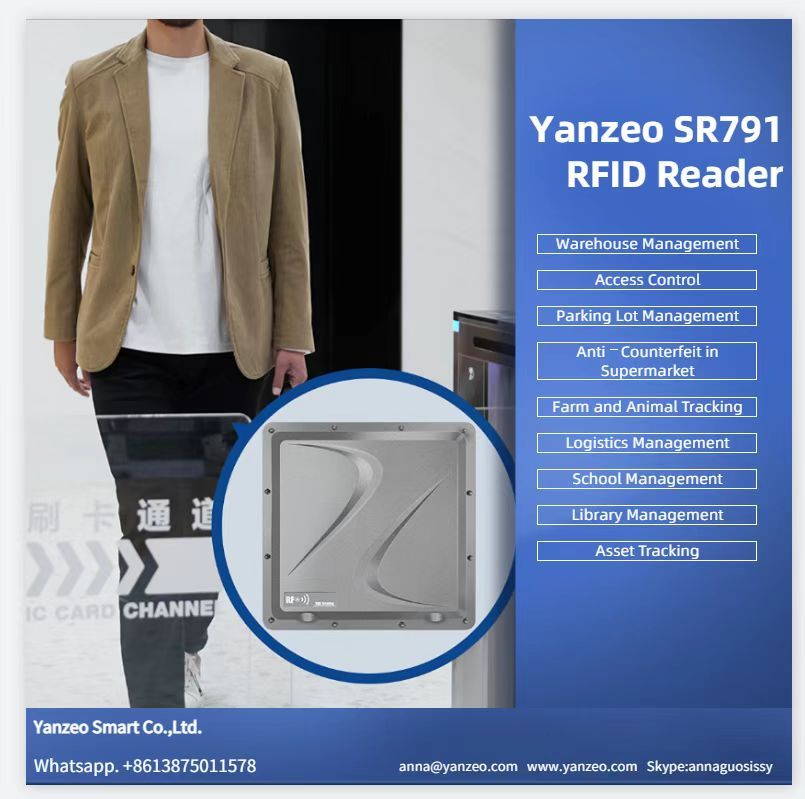

RFID technology has a wide range of applications, such as logistics and warehousing management, anti-counterfeiting traceability, industrial manufacturing, ETC, etc. Currently, typical application scenarios include animal chips, automotive chip anti-theft devices, access control, parking lot control, production line automation, material management, etc.

Short range RF products are not afraid of harsh environments such as oil stains and dust pollution, and can replace barcodes in such environments, such as tracking objects on factory assembly lines.

If you any question about RFID , please feel free to contact YANZEO.