Innovative Application of RFID Technology in Logistics Management

In recent years, with the increasingly mature application technology environment, IoT technology based on radio frequency identification (ultra-high frequency RFID) has emerged, attracting the attention of many industries. With the rapid development of information technology, the management of logistics, warehousing, and supply chain must keep up with the times and move towards industrial digitization and intelligence.

RFID (Radio Frequency Identification) is a communication technology that can identify specific targets and read and write relevant data through radio signals, without establishing mechanical or optical contact between the identification system and specific targets. A massive network system that enables the connection of people to people, people to things, and things to things at any time and place (anything, anytime, anywhere), in order to achieve intelligent recognition, positioning, tracking, monitoring, and management.

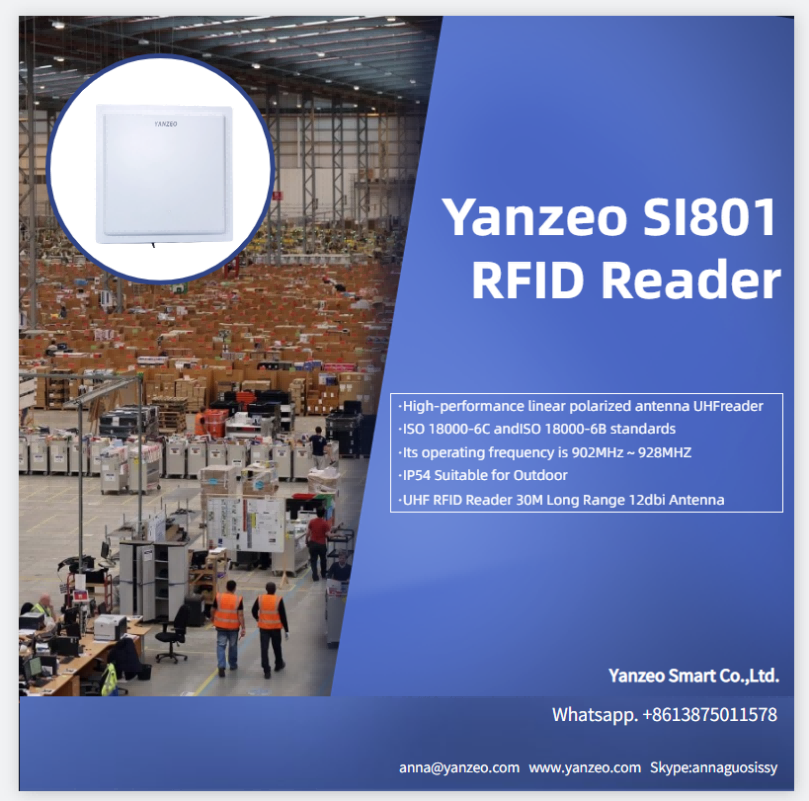

RFID has the technical characteristics of small device size, adaptability to harsh environments, repeated use, and safe use. With the help of RFID technology, the logistics industry can achieve management of various links in the logistics process, such as improving inventory management, timely replenishment, and effectively tracking transportation and inventory. For example, in terms of warehouse goods inbound and outbound and inventory counting, RFID can reduce manpower, reduce error rates, and improve efficiency.

1. Intelligent warehouse

By adopting key technologies in RFID warehouse management systems, the level of warehouse and logistics management technology can be significantly improved, and enterprises can obtain good investment returns. In the future, it can effectively avoid and reduce duplicate investments in enterprise information upgrading.

Intelligent logistics

The system should be able to achieve visual management of real-time warehouse data in the management center, truly achieving synchronization between actual logistics and data flow.

Realize the electronicization of pallets and loading and unloading points, achieve efficient inbound and outbound goods, effectively manage and allocate goods, achieve goods positioning, and quickly retrieve them.

Realize rapid acquisition of on-site physical information, compare it with ERP data, and ensure consistency between vouchers and materials.

The "automated sorting" solution based on RFID technology adopts more advanced automatic identification technology. Compared with traditional sorting systems, it has a lower error rate, is not affected by the direction of goods placement, can penetrate the vast majority of materials to read and store more material information, and better scalability.

By using RFID technology, the RFID reading and writing device is installed on key nodes of the conveyor line. The device senses the RFID electronic tag signal and collects its stored relevant information, and then uploads the tag information to the backend management supporting system. The system will effectively control the goods to come out of the corresponding express sorting port, thereby achieving automatic sorting, saving time and effort, improving accuracy and work efficiency.

Visualize logistics information in various stages, including logistics resource information, logistics demand information, logistics process, logistics status, logistics control, and logistics environment. Logistics visualization is aimed at logistics information, and its premise is the digitization of logistics.

With the development of technology, RFID intelligent warehouse management system is gradually replacing traditional warehouse management methods, providing strong support for enterprises with its high efficiency, accuracy, and automation characteristics.